Training

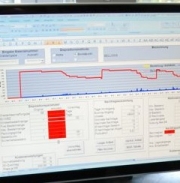

Materials Planning

Target Group

employees of materials planning and order management; planners for finished products, spare parts, materials etc.; operative purchasing

Prerequisites

working experience in materials planning

Duration

2 days

Languages

German (additional languages on demand)

Objectives

Increased goods availability with a decreased inventory level, confident handling of the material planning process, optimized utilization of the planning software, skillful use of methodic tools, performance increase through differentiation of what′s important and what′s unimportant, better understanding of the company′s process network, stronger awareness of costs

Contents

Objectives and methods of material planning; integration of material planning into Supply Chain Management; possibilities and responsibilities of material planning and scheduling

Inventory Management: inventory structuring; inventory causes and inventory responsibility; fast moving goods and slow moving goods; procedure, methods and tools of inventory controlling; risk analyses

Planning and Demand Analyses: Influence of forecasting; forecasting quality and forecasting horizon; from forecasting to material planning to demand planning; classification of demand and demand pattern

Order Quantities: Minimum order quantity; order quantity according to production quantity; "optimized" order quantity; Min-Max order quantity; Kanban; safety inventory

Ordering Date: Fixed vs. variable ordering rhythm; monthly scheduling; order point method; Kanban; safety time

Order Type: Automatic vs. manual order clearing; electronic vs. manual transmission; frame contracts; call-off orders; single orders

Objectives and Key Performance Indicators: Inventory level according quantity, money or days of inventory; inventory costs vs. handling costs; scrapping; delivery capability; extra costs

Inventory Management: inventory structuring; inventory causes and inventory responsibility; fast moving goods and slow moving goods; procedure, methods and tools of inventory controlling; risk analyses

Planning and Demand Analyses: Influence of forecasting; forecasting quality and forecasting horizon; from forecasting to material planning to demand planning; classification of demand and demand pattern

Order Quantities: Minimum order quantity; order quantity according to production quantity; "optimized" order quantity; Min-Max order quantity; Kanban; safety inventory

Ordering Date: Fixed vs. variable ordering rhythm; monthly scheduling; order point method; Kanban; safety time

Order Type: Automatic vs. manual order clearing; electronic vs. manual transmission; frame contracts; call-off orders; single orders

Objectives and Key Performance Indicators: Inventory level according quantity, money or days of inventory; inventory costs vs. handling costs; scrapping; delivery capability; extra costs

Methods

lecture, teamwork, one-on-one activities, computer-aided simulations